Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Introduction – The City’s Pulse Goes Electric

In recent weeks, headlines across Reuters, Bloomberg and even Instagram’s “Explore” tab have been dominated by the meteoric rise of electric bicycles and scooters. City streets in Berlin, San Francisco, Seoul and Nairobi are now peppered with whirring, hand‑held “e‑mobility” devices, all of them pointing to a single, rapid solution for last‑mile transportation: a compact, efficient gear motor—commonly known as a reducer motor. The micro‑mobility boom is not just a fad; it’s a tangible response to growing climate concerns, aging urban infrastructures, and the lasting impact of COVID‑19 on walking and biking habits. The surge in demand for these devices has put the gear motor at the centre of the transportation revolution, redefining what it means to move through a city efficiently and sustainably.

Gear Motors: From Factory Floor to City Streets

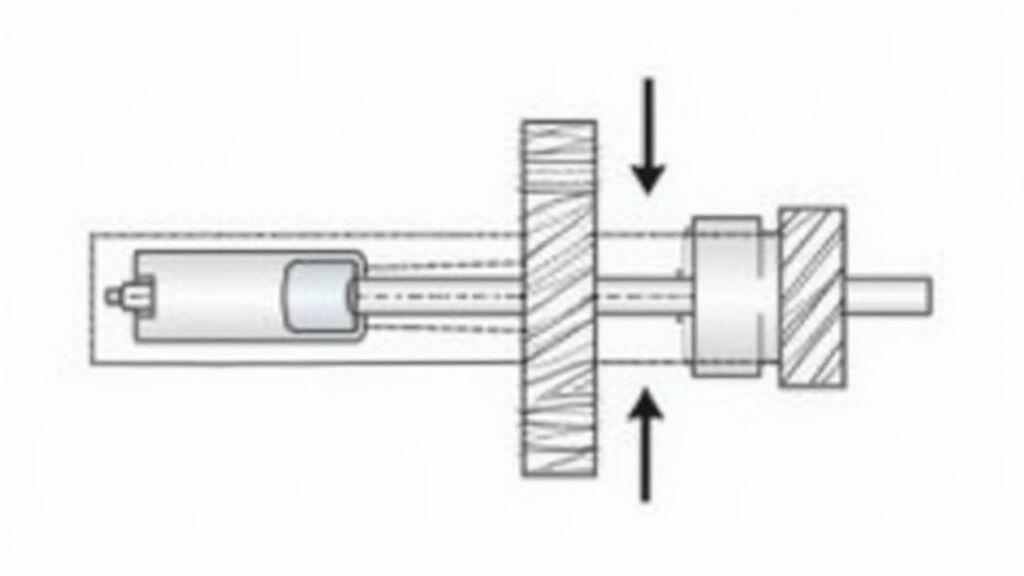

A gear motor is a self‑contained assembly that combines a DC motor with a gearbox. The motor provides the raw torque, while the gearbox reduces speed and increases torque at the output shaft—exactly what e‑bikes and scooters need to generate forward thrust from small, lightweight frames. The key advantages that empower these new vehicles are:

Gear motors that meet e‑mobility specifications are usually made with a planetary or helical gear set rated for low backlash and high precision. These designs provide the smoothened torque output needed for a pleasant rider experience, avoiding the jerky bursts that can come from direct‑drive systems at low speeds. This precision is vital when thousands of users in a city rely on the same hardware to go from bike‑park to workplace smoothly and safely.

The Trend: Micro‑Mobility as an Urban Solution

The COVID‑19 pandemic taught us that our cities are fragile and synchronous. Social distancing pushed many to use bicycles; lockdowns made people skip public transport. When restrictions eased, the DAM (Direct‑access mobility) market boomed, giving rise to corporate scooter‑sharing programs and town‑wide e‑bike rental networks. According to a recent report by McKinsey & Co., the micro‑mobility segment is projected to exceed $130 billion globally by 2029— a 250‑percent growth from 2022. That growth is fueled by:

All these catalysts are squeezing a high‑performance, cost‑effective gear motor into the workflow of each e‑mobility device. Gear motor manufacturers are racing to innovate beyond the industry average, offering higher torque, reduced losses, and better heat management to improve runtime and safety.

Market Demand Dynamics for Gear Motors

For manufacturers, the quick shift from a niche component to a mainstream driver of global infrastructure means they need to:

The open‑source community is also stepping in, designing inexpensive “micro‑gear” kits that hobbyists use to convert their own bikes. This trend fosters an ecosystem of continuous innovation: if a design flaw is spotted on a prototype, it can be corrected quickly in open‑source firmware and re‑launched from the community.

Sustainability Synergies: Gear Motors and the Clean‑Tech Future

Beyond the immediate gains in urban efficiency, gear motors serve a larger purpose: they make renewable energy technologies more practical on a larger scale. In wind turbines, for instance, gear motors link the rotor’s slow rotation to faster generator speeds, enabling current, readily available generators to function efficiently. In solar‑powered micro‑grids, tiny gear motors help moderate loads, smoothing out intermittent output. In all these applications—renewable sensors, electric textile machinery, water‑pumping systems—the gear motor’s key role is the transformation of raw kinetic energy into usable, controllable output. So as cities surface, the same technology that powers e‑mobility will also help hospitals, schools, and factories use renewable energy more effectively.

Future Outlook: Merging Tech and Mobility

In the not‑so‑distant future, the synergy between refinement in gear motor components—such as digital speckled magnetic bearings—and the global shift towards sustainable transportation will sharpen even more. Manufacturers already talk about:

If these innovations come to fruition, the e‑mobility industry can look forward to vehicles that are not only ultra‑compact but also digitally managed—a true interconnected, low‑carbon mobility civilization.

Conclusion – Gear Motors at the Heart of an Urban Revolution

The unfolding trend in micro‑mobility is more than just a new way to travel; it is a sign of systemic change. From the streets of London to the riding lanes in Lagos, the common thread is the humble gear motor—a small, efficient powerhouse that spins the wheels of our daily commute. As governments roll out clean‑air policies, investment flows into shared transport platforms, and tech firms develop smarter, more reliable motor designs, gear motors will continue to be the linchpin in a sustainable urban future. The year 2025 may already feel like the beginning of that future, but the earnest promise remains: a city that moves on clean, quiet, re‑chargeable wheels, powered by technology that is compact, precise, and endlessly adaptable—thanks to the remarkable gear motor.

Leave A Reply

Your email address will not be published. Required fiels are marked